Electronics Laboratories

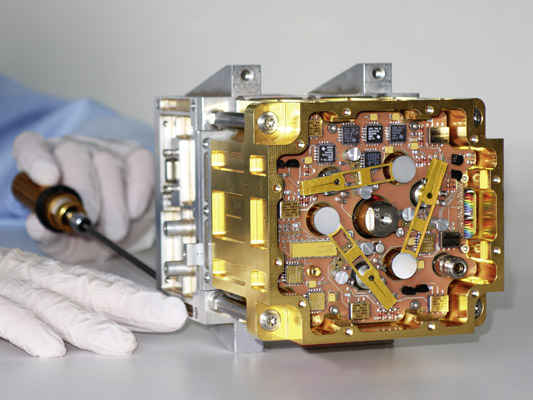

The PMOD/WRC operates two electronics laboratories. In the labs, electronic circuits for space applications, as well as high-precision ground-bound measuring instruments, are developed and built. For this purpose, the laboratories are equipped with special tools and measuring instruments.

We are able to produce printed circuits for prototypes ourselves using a PCB milling machine. With the vapor-phase soldering machine, double-sided printed circuit boards can be manufactured. The Reflow-Station allows reworking of already equipped boards. For special cleanliness requirements during production, a clean bench as well as a clean-room are available.

Development of Space Hardware

The circuit design is usually completed on the PC. We use Altium software to draw the schematics and later the layout of the circuit board. The functionlity of the circuit is then verified by simulating the circuit using Altium if required. As soon as the simulations yield satisfactory results, the first prototype is built and measured in the electronics laboratory. The prototype is then further developed and improved until the circuit meets all requirements.