A cleanroom is an environment, typically used in the manufacturing, scientific research, semiconductor and aerospace industries, which has a low level of environmental pollutants such as microbes, aerosol particles, and chemical vapors. It is also an environment where temperature, humidity and pressure can be controlled.

In order to achieve low pollutant levels, the cleanroom air is filtered using High Efficienty Particulate Air (HEPA) filters to trap aerosols larger than about 0.5 μm in diameter. Ultra Low Particulate Air (ULPA) filters may be used for critical applications where the highest levels of cleanliness are required. As personnel are one of the largest sources of cleanroom contamination, special head and body clothing must be worn.

In order to put the cleanliness of cleanroom environments into perspective, a comparison with ambient aerosol concentrations is useful. Typical ambient concentrations are about 1 x 107 m-3 when considering aerosol diameters >0.5 μm. This would correspond to an ISO (International Standards Organization) 9 cleanroom. On the other hand, an ISO 1 cleanroom has an aerosol concentration limit of 12 m-3 for diameters <0.3 μm.

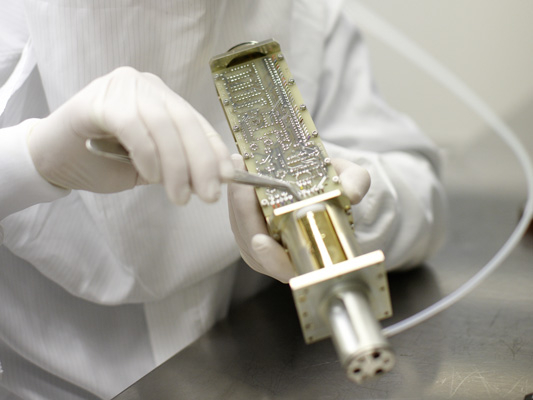

In order to achieve the high standards required of space applications, the PMOD/WRC has a dedicated cleanroom for the manufacture and assembly of instruments. Figures 1 and 2 illustrate PMOD/WRC personnel during the assembly of radiometers. In addition to the cleanroom, several clean-benches are also in use throughout the PMOD/WRC.